Sizing Screens

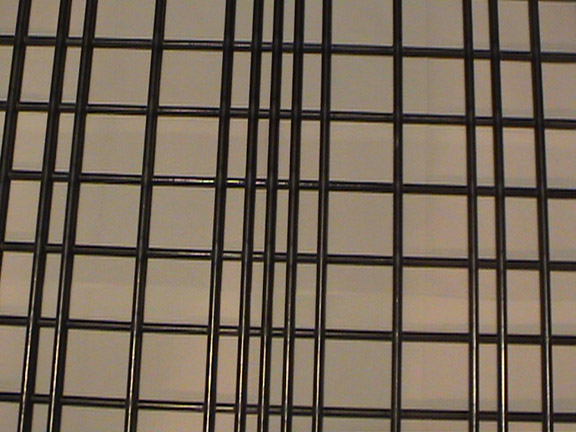

Welded screens are guaranteed to last three times longer than woven screens because woven screens have crimps which weaken the wire and welded wire is much more abrasive resistant.

Welded screens are guaranteed to last three times longer than woven screens because woven screens have crimps which weaken the wire and welded wire is much more abrasive resistant.- Welded screens give up to 20% more throughput than any other media.

- Screen changeouts are reduced and are predictable.

- Wires can be clustered to protect support bars.

- A smaller piece of screen or “wearpad” can be welded on a screen in the feed area to strengthen the screen locally and to significantly increase wear life, while maintaining open area.

- Virtually any hole or slot size can be supplied.

- Welded screens are easier to install as they are arched to fit the deck

- Customers have stated that plugging/blinding problems were eliminated with welded screens.

- The hole size is always maintained.

- Welded screens are lighter than woven, plate or synthetics.

Opening sizes table

The following table shows the most commonly used square openings. However, virtually any size opening can be supplied. Similarly, any slot combination can be provided for slotted screens.

H – HEAVY | MH – MEDIUM HEAVY | M – MEDIUM | ML – MEDIUM LIGHT

|

Square |

GRADE |

Wire Diameter |

% Open |

Weight |

||

|

Fraction |

Decimal |

|||||

|

8″ |

M |

3/4 |

0.750 |

83.6% |

4.12 |

|

|

6″ |

M |

3/4 |

0.75 |

79.0% |

5.35 |

|

|

5″ |

MH |

3/4 |

0.75 |

75.6% |

6.27 |

|

|

4″ |

MH |

3/4 |

0.75 |

70.9% |

7.60 |

|

|

3 3/4″ |

MH |

3/4 |

0.75 |

69.4% |

8.02 |

|

|

3 1/2″ |

H |

3/4 |

.75 |

67.8% |

8.49 |

|

|

3 1/4″ |

H |

3/4 |

.75 |

66.0% |

9.02 |

|

|

3″ |

H |

3/4 |

.75 |

64.0% |

9.62 |

|

|

2 7/8″ |

MH |

5/8 |

0,625 |

67.5% |

7.16 |

|

|

2 3/4″ |

H |

5/8 |

0,625 |

66.4% |

7.42 |

|

|

2 5/8″ |

H |

5/8 |

0,625 |

65.2% |

7.71 |

|

|

2 1/2″ |

H |

5/8 |

.625 |

64.0% |

8.02 |

|

|

2 3/8″ |

H |

5/8 |

.625 |

62.7% |

8.35 |

|

|

2 1/4″ |

H |

5/8 |

.625 |

61.2% |

8.71 |

|

|

..2 1/8″ |

MH |

1/2 |

0.5 |

65.5% |

6.11 |

|

|

2″ |

MH |

1/2 |

0.5 |

64.0% |

6.41 |

|

|

1 7/8″ |

M |

3/8 |

0.375 |

69.4% |

4.01 |

|

|

1 3/4″. |

M |

3/8 |

0.375 |

67.8% |

4 24 |

|

|

1 5/8″ |

M |

3/8 |

0.375 |

66.0% |

4.51 |

|

|

1 1/2″ |

MH |

3/8 |

0.375 |

64.0% |

4.81 |

|

|

1 3/8″ |

MH |

3/8 |

0.375 |

61.7% |

5.15 |

|

|

1 1/4″ |

MH |

3/8 |

0.375 |

59.2% |

5.55 |

|

|

1 3/16″ |

H |

3/8 |

.375 |

57.8% |

5.77 |

|

|

1 1/8″ |

MH |

5/16 |

0.3125 |

61.2% |

4.36 |

|

|

1 1/16″ |

MH |

5/16 |

0.3125 |

59.7% |

4.56 |

|

|

1″ |

MH |

5/16 |

0.3125 |

58.0% |

4.77 |

|

|

15/16″ ‘ |

MH |

1/4 |

0.25 |

62.3% |

3.38 |

|

|

7/8″ |

MH |

1/4 |

0.25 |

60.5% |

3.56 |

|

|

13/16″ |

MH |

1/4 |

0.25 |

58.5% |

3.77 |

|

|

3/4″ |

MH |

1/4 |

0.25 |

56.3% |

4.01 |

|

|

11/16″ |

H |

1/4* |

0.25 |

53.8% |

4.28 |

|

|

5/8″ |

H |

1/4* |

0.25 |

51.0% |

4.58 |

|

|

9/16″ |

H |

1/4* |

0.25 |

47.9% |

4.93 |

|

| * Special abrasive resistant wire. | ||||||